A new light-emitting-diode (LED) could greatly improve the cost and efficiency of remote sensing systems and infrared screens.

In a paper published in Optica, researchers in the Cockrell School of Engineering at The University of Texas at Austin outline a new LED sensor component in the "mid-infrared" wavelength – where thermal imaging can pick up things people can't see, such as gas leaks in pipelines and excess emissions from smoke stacks. The researchers say their device offers a path toward significant improvement in performance over existing infrared LEDs, making them better suited to spot excess leaks and emissions.

"Existing sources are pretty expensive, and they're often too low power for a lot of these applications," said Seth Bank, a professor in the Department of Electrical and Computer Engineering who is the principal investigator on the project. "The way we built these LEDs, we get this direct improvement in the output power even just in this first pass."

Andrew Briggs, one of Bank’s graduate students, led the research. Associate professor of electrical and computer engineering Dan Wasserman, members of his Mid-IR Photonics group and collaborators at UMass Lowell and the University of Illinois at Urbana-Champaign also worked on the project.

Large-scale optical remote sensing can be a challenge because of high costs. Lasers at the wavelength of the team's device can cost anywhere from $5,000 to $150,000, depending on power, wavelength tunability and modulation bandwidth.

The ability to easily optically inspect for leaks in gas pipelines represents an important step forward in environmental monitoring. High costs have forced organizations to pursue complicated plans for monitoring, such as installing expensive systems on helicopters that fly around looking for leaks, because of a lack of readily available, inexpensive sensors that can be deployed widely.

"A much more scalable approach would be possible if you could make these compact and lightweight solid-state sensor parts for just a few cents; you could put them everywhere, and you wouldn't have to do these elaborate things," Bank said.

And that’s exactly the kind of system these LEDs unlock. Beyond environmental applications, the devices could cut costs for making infrared and LED screens, which are common in televisions and other large displays. Infrared screens display images that can only be seen by infrared (night vision) cameras, making them important for recreating and simulating thermal signatures.

The key to the research lies in a sort of "wacky materials" dynamic, Bank said. Bringing metals inside the LED itself can help to confine light and increase the amount of light that escapes from the LED and into the outside world.

“Typically, for LEDs and other light-based devices, one first grows the semiconductor material, and then looks for a way to encapsulate the grown devices (sometimes in metal) in such a way that the emitted light is directed outward,” Wasserman said. “However, the available architectures are limited, and it is the optical environment outside of the device that is typically engineered.”

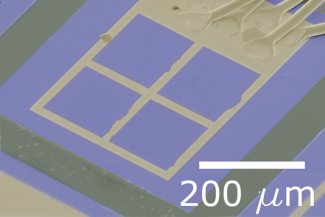

But the researchers "doped" the semiconductor underneath the LED active region – where light is actually produced – by adding a bunch of electrons that effectively turn it into a metal. In doping it so heavily, the researchers say, they have effectively grown a semiconductor metal directly into their device layer stack, simplifying processing and significantly improving device performance.

Their process allows the LEDs to more efficiently emit light, creating a more intense beam, from an active region approximately 1/1000th the thickness of a human hair.

All light-emitting devices lose some of their light as waste, reducing efficiency and intensity of the beams. The new devices minimize that light loss, leading to a stronger beam, the researchers say.

Bank and Wasserman both view the engineering of how light-matter interact, and specifically, light generation and detection in semiconductors with engineered metal/dielectric environments as a focal point of their research. This work, like many of the efforts in their labs, share a common theme of taking core scientific principles and finding ways to leverage them to make devices that can do things that aren't possible today.

"Our work is a nice mix of fundamental physics and science, with an eye toward new technologies that can make a difference," Wasserman said. "We are trying to leverage fundamental and new material phenomena for real-world applications."